Automation

Since 2018, the Yuzhnaya Agrofirm has been actively introducing automation methods for various stages of work, thanks to which the efficiency of using available resources is increased and realistic forecasts for production development are drawn up, taking into account key indicators.

Automation of production is carried out simultaneously in several directions. One of them is the automation of management and accounting of the harvesting process. Control with subsequent analysis is carried out through the “Crop Control Center” service, combined with a monitoring system based on GLONASS/GPS. Thanks to a streamlined online process, specialists determine the grape yield per unit area during mechanized harvesting, analyze the data obtained and the factors that influenced them, which subsequently allows them to build improved work tactics.

During the harvesting period in 2019, at the weigh station located in the village. Tamansky Temryuk district, modern technologies were installed and tested: a Galileosky satellite monitoring device, a Matrix reader, GSM antennas, a module for receiving and transmitting data from electronic scales. Their use made it possible to speed up the process of generating an electronic invoice in the Harvest Control Center service and eliminate errors associated with human actions. It is planned to automate the generation of primary documentation based on the results of weighing at weight control points of departments and acceptance points.

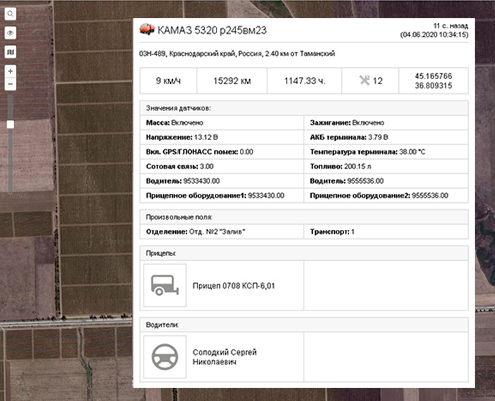

The introduction of a satellite vehicle monitoring system and equipping fuel dispensers with GLONASS/GPS systems made it possible to organize the dispensing of fuel to personnel via RFID cards and to take the movement of fuel under controlled control. As a result, the risks associated with the unauthorized use of fuels and lubricants have been minimized and consumption rates have been streamlined. Work is underway to fully automate the accounting of fuel movement, starting from the moment it is received in the gas station tanks and ending with its subsequent use. The process of entering data on refueling and fuel consumption into the waybill in 1C UPP has been automated.

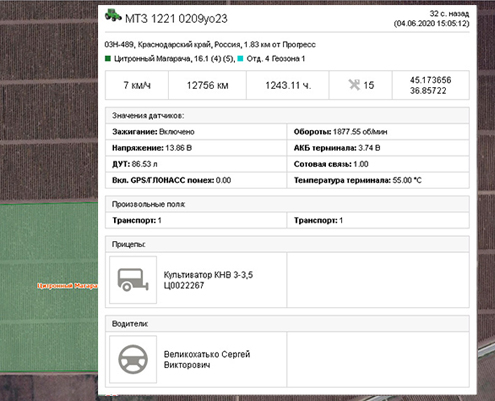

The use of satellite monitoring of agricultural machinery has optimized its operation and the consumption of materials during agricultural operations. The ability to determine the fact that equipment is in the field, to see the calculation of the area processed by agricultural equipment allowed to increase the time of its operation, reduce losses and control the further development of the situation, thereby optimizing management. Today, more than 400 moving and stationary objects are connected to the satellite monitoring system.

In February 2020, the Mobile Agronomist information and analytical system was introduced into production. To implement this project, our own specialized software was created. The development automates the organization and accounting of technological processes, systematizes data, keeps it up to date and replicates it in 1C UPP. Based on the information received, primary accounting documents are automatically generated: waybills, orders for manual work.

Much attention is paid to creating a database for obtaining data for planning work in the field. In 2019, thanks to the operation of 13 weather stations equipped with numerous sensors, the collection of information about:

- precipitation

- temperature and humidity of air and soil

- atmospheric pressure level

- moisture content of grape leaves

- solar activity

- wind speed and direction

The listed indicators are very important for increasing the quantity and improving the quality of the crop. Collection, subsequent transmission and processing of data are carried out automatically. Specialists receive all the necessary information and, based on it, make decisions on planning agricultural operations. In the future, the use of weather stations will make it possible to generate long-term climate data and use this resource in everyday agronomic work.